Thermal Spray

High-performance coating technology for wear, corrosion, and heat protection across industrial applications.

About Thermal Spray

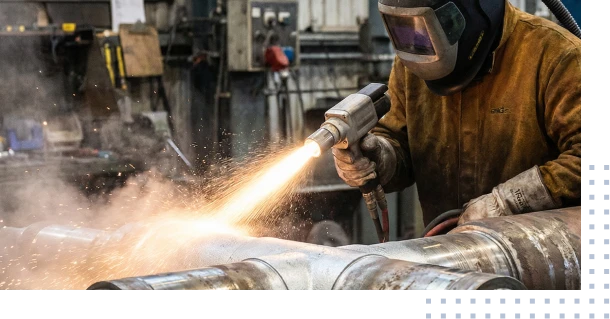

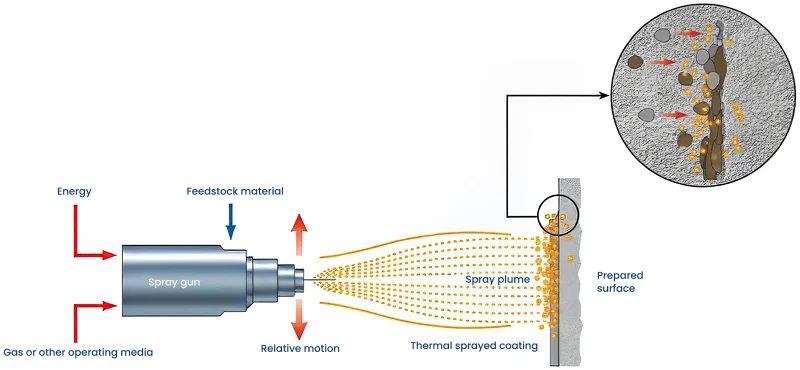

Thermal spray is a surface coating process used to apply metals, alloys, or ceramics onto a substrate to enhance its resistance to wear, corrosion, erosion, and high temperatures. The process involves heating the coating material in powder or wire form and projecting it onto a prepared surface using a high-velocity gas or plasma jet.

At Shivshakti Metal, we specialise in thermal spray materials, powders, and accessories, providing complete coating solutions for a variety of industries, from power generation, oil & gas, and aerospace to manufacturing and heavy engineering.

As a trusted thermal spray supplier and manufacturer in India, we also distribute Oerlikon Metco and Kennametal products to meet international standards for performance and reliability.

Product Range

Under the Thermal Spray consumables category, you’ll find specific sub-pages including:

Thermal Spray Powders & Accessories

covering supplier/ manufacturer items for various thermal spray technologies.

Explore Product Range

Metco Thermal Spray Powders

dedicated page for Metco brand powders and materials

Explore Product Range

Cobalt Base Welding Wire and Powder

dedicated page for Metco brand powders and materials

Explore Product Range

MIG & Powders for Thermal Spray

dedicated page for Metco brand powders and materials

Explore Product RangeTypes of Thermal Spray Processes

Different coating requirements call for different spray technologies. At Shivshakti Metal, we provide materials suitable for all major thermal spray techniques:

Flame Spray Coating

A cost-effective thermal spray method where powder, wire, or rod materials are melted by a flame (oxy-acetylene or oxy-propane) and sprayed onto the work surface using compressed air.

Advantages:

- Ideal for large surface areas

- Lower equipment cost

- Suitable for metals, ceramics, and plastics

Applications:

- Shafts, pumps, bearing housings, and hydraulic rods

- Repair of worn components

- Anti-corrosion coatings in marine and industrial environments

Plasma Spray Coating

An advanced thermal spray technique using a high-temperature plasma jet (up to 15,000°C) to melt and propel coating materials onto the substrate, forming dense, high-performance coatings.

Advantages:

- Produces very strong, uniform coatings

- Works with refractory materials (ceramics, carbides, oxides)

- Suitable for critical industrial and aerospace components

Applications:

- Turbine blades, piston rings, aerospace engine parts

- Medical implants and precision components

- High-temperature insulation and oxidation protection

Why Thermal Spray Coatings?

Thermal spray coatings are ideal for protecting and restoring components exposed to extreme service conditions. They offer:

- Enhanced surface hardness and wear resistance

- Superior corrosion and oxidation protection

- Reduced maintenance and downtime

- Extended component lifespan

- Compatibility with metals, ceramics, and composites

Applications

Thermal spray coatings are widely used across industries for protection, restoration, and performance enhancement:

Power generation (turbine blades, pump parts)

Oil & gas (valve seats, shafts, sealing surfaces)

Marine and offshore structures

Aerospace and automotive industries

Chemical and process equipment

Additional Processes

Besides flame and plasma spray, Shivshakti Metal also supports materials for:

HVOF (High Velocity Oxy-Fuel)

Arc Spray

Combustion Wire Spray

Principle of Thermal Spraying

Why Choose Shivshakti Metal?

Manufacturer and trader of high-quality thermal spray and their consumables like powders and materials

Authorised distributor of Oerlikon Metco and Kennametal

Wide range of metal, alloy, and ceramic powders for every spray process

Proven coating performance and consistent material quality

PAN India and export-ready supply network