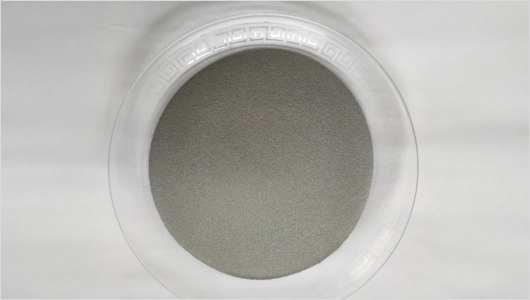

Cobalt-Based Welding Powder

High-performance cobalt-based welding powders engineered for superior wear, corrosion, and high-temperature resistance.

About Cobalt-Based TIG & MIG Welding Powders

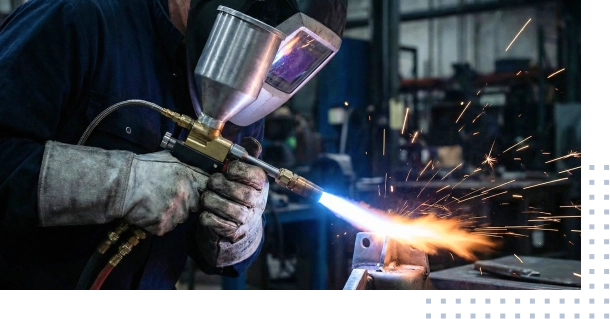

At Shivshakti Metal, we supply and distribute cobalt-based welding powders suitable for TIG welding, PTA (Plasma Transferred Arc) welding, MIG welding, and hardfacing applications.

These powders are formulated using premium cobalt alloys such as Stellite 6, Stellite 12, and Stellite 21 equivalents, known for their outstanding hardness, toughness, and metallurgical bonding properties.

Our Cobalt Base TIG powders are ideal for applications that demand resistance to extreme wear, heat, and corrosion, ensuring long-lasting surface protection under the toughest industrial conditions.

As a leading cobalt-based powder supplier in India, Shivshakti Metal ensures each batch meets international quality standards, supporting industries like oil & gas, power generation, valves, pumps, and tool manufacturing.

Product Range of Cobalt-Based Welding Powder

Cobalt Base Co6 Powder (Stellite® 6 Equivalent)

A versatile cobalt-chromium alloy powder offering outstanding wear, heat, and corrosion resistance — suitable for general-purpose hardfacing.

Composition: Co + Cr + W + C

Applications: Valve seats, pump shafts, turbine blades, and cutting edges exposed to friction or oxidation.

Cobalt Base Co12 Powder

High-strength alloy powder with excellent hardness, edge retention, and thermal fatigue resistance for demanding conditions.

Composition: Co + Cr + Mo + W

Applications: Dies, sealing faces, cutting tools, and forming moulds operating under high-temperature or abrasive conditions.

Cobalt Base Co21 Powder

Formulated for superior metallurgical bonding, ductility, and crack resistance, this powder provides enhanced toughness and corrosion resistance.

Composition: Co + Cr + Ni + Mo

Applications: Oil & gas components, chemical processing valves, and high-pressure sealing surfaces.

Cobalt Base TIG Rods & Custom Powders

Custom-engineered cobalt alloys designed for TIG and PTA torch flow applications, ensuring smooth deposition and uniform coating quality.

Composition: Tailored to process and substrate requirements

Applications: Hardfacing, repair, and restoration of industrial machinery, rollers, and pump components.

Key Features

- Excellent wear and corrosion resistance at elevated temperatures

- Smooth flow characteristics ensure consistent weld deposits

- Stable mechanical strength and hardness up to 45–50 HRC

- Compatible with PTA, TIG, MIG, and laser welding systems

- Ideal for surface restoration and hardfacing of industrial components

Applications

Hardfacing of cutting tools, turbine blades, and valve seats

Surface protection for components exposed to high wear and temperature

Repair and restoration of industrial parts in power and oil & gas sectors

Metal-to-metal wear resistance in pumps, shafts, and dies

Overlay coating for chemical and marine equipment

Advantages

High Hardness (up to 50 HRC)

Excellent Wear Resistance

Thermal & Oxidation Stability

Strong Metallurgical Bonding

Smooth Deposition Flow

Why Choose Shivshakti Metal for Cobalt Based Welding Powder ?

Trusted supplier of cobalt-based welding powders across India

Distributor of imported Metco and Kennametal-grade powders

High purity and consistent flow rate for TIG & PTA welding

Technical guidance for hardfacing and repair welding operations

PAN-India availability with certified test reports (TC)

FAQs

1. What are cobalt-based powders used for?

Cobalt-based powders are used for wear-resistant coatings, hardfacing, and high-temperature applications where surface protection is critical.

2. Can these powders be used for TIG welding?

Yes. Our cobalt base TIG powders are formulated for smooth flow, easy melting, and excellent bonding in TIG and PTA welding.

3. What hardness can I expect from Co6 or Co21 powders?

A Typically between 40–50 HRC, depending on the alloy and heat treatment.

4. Are these powders suitable for oil & gas and chemical plants?

Yes. Their corrosion and oxidation resistance make them ideal for pumps, valves, and pipeline equipment used in such industries.

5. Do you supply imported cobalt-based powders?

Yes, Shivshakti Metal supplies both Fusion Make and Kennametal imported cobalt-based powders for industrial applications.

Request a Quote

Related Products

Thermal Spray Powders & Accessories

covering supplier/ manufacturer items for various thermal spray technologies.

Explore Product Range

Metco Thermal Spray Powders

dedicated page for Metco brand powders and materials

Explore Product Range

Cobalt Base Welding Wire and Powder

dedicated page for Metco brand powders and materials

Explore Product Range

MIG & Powders for Thermal Spray

dedicated page for Metco brand powders and materials

Explore Product Range