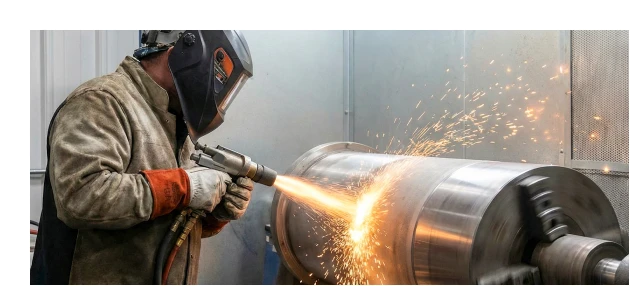

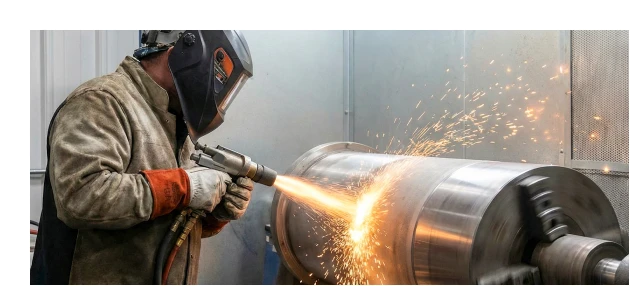

Thermal Spray Powders & Consumables

High-performance metal and alloy powders engineered for superior bonding, surface protection, and restoration across thermal spray processes.

About Thermal Spray Powders

At Shivshakti Metal, we manufacture and supply a wide range of thermal spray powders (aka metal spray powders) formulated for flame spray, plasma spray, and spray welding applications. Our metal spray powders are designed to deliver consistent coating quality, strong adhesion, and excellent wear and corrosion resistance on a variety of base materials.

As one of the trusted thermal spray powder manufacturers and suppliers in India, we also distribute globally recognised brands such as Oerlikon Metco and Kennametal. From nickel-, cobalt-, and iron-based alloys to ceramic and carbide composites, our powders are engineered to meet the demanding requirements of industry, ensuring long-lasting surface protection and improved component life.

Whether used for maintenance, repair, or production coating, our powders support industries such as power generation, petrochemical, aerospace, and heavy fabrication.

Product Range of Thermal Spray Powders

At Shivshakti Metal, we supply a comprehensive selection of thermal spray and hardfacing powders, sourced from leading global manufacturers such as Oerlikon Metco and Kennametal.

Our range includes nickel, cobalt, tungsten carbide, and composite powders designed for flame spray, plasma spray, and HVOF coating applications.

StelliteTM Thermal Spray & Hardfacing Powders

High-performance cobalt-chromium-based powders designed for PTA, plasma spray, laser, and HVOF applications, ensuring excellent wear, corrosion, and heat resistance.

Composition: Co + Cr + W + C

Applications: Hardfacing of valve seats, cutting tools, turbine components, and pump sleeves.

Tungsten Carbide Thermal Spray & Hardfacing Powders

Engineered tungsten carbide-based powders that deliver exceptional hardness and erosion resistance under high-stress environments.

Composition: WC + Co / WC + Ni / WC + Cr

Applications: Aerospace, mining, and oil & gas — ideal for wear-prone machinery parts and coatings.

StelliteTM Hardfacing Rods & Electrodes

Cobalt-chromium (CoCr) rods and electrodes for GTAW, TIG, and oxy-fuel welding processes, ensuring dense, crack-free deposits with superior bonding strength.

Composition: Co + Cr + Mo + W

Applications: Cutting tools, dies, sealing faces, and corrosion-resistant overlay coatings.

StelliteTM Cored Hardfacing Wire

CoCr-based cored wires designed for MIG, GMAW, and SAW processes, offering excellent metallurgical bonding and high deposition efficiency.

Composition: Cobalt-Chromium-Molybdenum alloy core with metal binder

Applications: Valve seats, rollers, and industrial repair coatings.

Tungsten Carbide Composite Brazing Rods

Cemented tungsten carbide rods with a nickel-silver matrix, providing exceptional bonding strength and abrasion resistance.

Composition: WC + Ni / WC + NiCr

Applications: Oxy-fuel hardfacing, drill bits, earth-moving tools, and wear surfaces.

NiCarTM Hardfacing Rods

Nickel-bonded tungsten carbide rods offering superior metallurgical bonding, smooth flow, and high toughness.

Composition: WC + Ni

Applications: Repair and rebuilding of dies, mixing blades, pump parts, and machine shafts.

Tungsten Carbide Filled Hardfacing Rods

High-hardness rods with uniform carbide dispersion, providing maximum resistance to abrasion and erosion in high-pressure environments.

Composition: WC + Ni / WC + Co

Applications: Oilfield tools, dredging pumps, earthmovers, and heavy fabrication parts.

Macrocrystalline Tungsten Carbide Powders

A stable, coarse-grain tungsten carbide material used as a wear modifier in various hardfacing and coating applications.

Composition: WC (Macrocrystalline)

Applications: Hardfacing alloys, wear plates, and coatings exposed to heavy abrasion.

KenfaceTM Cemented Carbide Powders

Fully sintered and crushed cemented tungsten carbide powders, offering a perfect balance of toughness and hardness.

Composition: WC + Co

Applications: Mining, construction, and thermal spray coatings for wear resistance.

Spherical Tungsten Carbide Pellets

High-strength, abrasion-resistant spherical tungsten carbide granules designed for consistent coating density and uniform application.

Composition: WC + Co / WC + Ni

Applications: Hardfacing, HVOF spraying, and powder metallurgy operations.

Key Features

- Consistent particle size and controlled flowability for stable spray performance

- Compatible with major spray systems — flame, plasma, and HVOF

- Excellent bonding strength and coating adhesion

- High wear, corrosion, and heat resistance

- Custom powder blends available for specific process and substrate needs

Applications

Surface restoration and dimensional repair

Wear- and corrosion-resistant coatings

High-temperature oxidation and erosion protection

Hard-facing and component rebuilding

Electrical insulation coatings in industrial machinery

Advantages

High Bond Strength

Uniform Coating Finish

Corrosion & Oxidation Resistance

Custom Alloy Formulations

Longer Service Life

Energy Efficient Application

Why Choose Fusion WireTM for Thermal Spray Powders?

Manufacturer & distributor of global brands like Oerlikon Metco and Kennametal

Custom powder formulations to match specific coating needs

PAN-India supply and export-ready distribution network

Quality-controlled production ensuring repeatable results

Technical support for process selection and coating performance

FAQs

1. What are thermal spray powders used for?

Thermal spray powders are used to coat metal surfaces to improve wear, corrosion, and heat resistance. They restore worn components and enhance surface performance in industrial equipment.

2. What types of powders are available at Shivshakti Metal?

We offer nickel-based, cobalt-based, iron-based, carbide, and ceramic powders compatible with plasma, flame, and HVOF spray systems.

3. Can I use these powders for spray welding?

Yes. Our spray welding powders are formulated for excellent wetting and bonding during flame or plasma spraying.

4. Do you supply imported brands like Metco and Kennametal?

Yes. Shivshakti Metal is an authorised distributor for Oerlikon Metco and Kennametal thermal spray powders in India.

5. Do you provide custom powder grades?

Yes, we can supply customised compositions to match your coating application, substrate type, and operating environment.

Request a Quote

Related Products

Thermal Spray Powders & Accessories

covering supplier/ manufacturer items for various thermal spray technologies.

Explore Product Range

Metco Thermal Spray Powders

dedicated page for Metco brand powders and materials

Explore Product Range

Cobalt Base Welding Wire and Powder

dedicated page for Metco brand powders and materials

Explore Product Range

MIG & Powders for Thermal Spray

dedicated page for Metco brand powders and materials

Explore Product Range