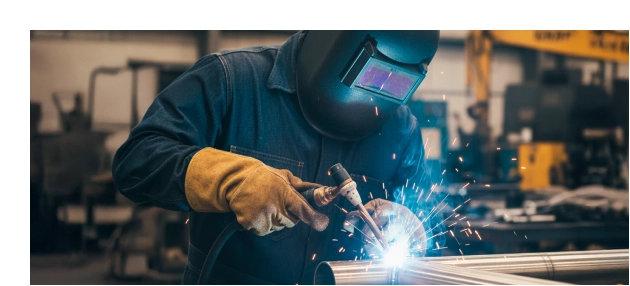

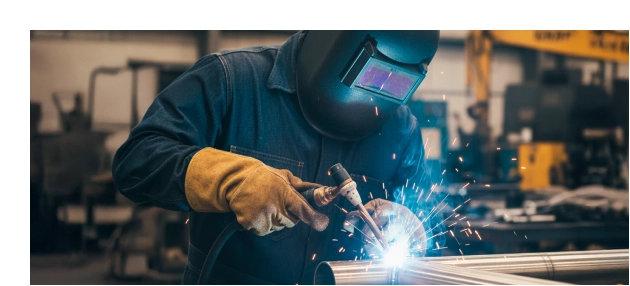

Tungsten Rods & Electrodes Manufacturer

High-performance tungsten rods and TIG electrodes engineered for precision welding, superior arc stability, and long service life across all industries.

About Tungsten Rods

At Shivshakti Metal, we manufacture and supply tungsten rods and tungsten electrodes designed for TIG (Tungsten Inert Gas) welding applications.

Renowned for their exceptional heat resistance, durability, and electrical conductivity, our tungsten rods deliver clean, stable arcs and ensure precise control during high-quality welding operations.

Our range of TIG electrodes is suitable for both manual and automatic welding systems, covering all major grades such as pure tungsten, thoriated, ceriated, lanthanated, and zirconiated tungsten electrodes.

As a leading tungsten rod supplier in India, Shivshakti Metal provides industrial-grade electrodes and tungsten bars used across aerospace, automotive, fabrication, and power plant industries, where precision and consistency are critical.

Grade Specifications

WP (Pure Tungsten)

Color Code: Green

Composition:

99.5% Tungsten

Applications & Benefits:

Suitable for AC welding of aluminum and magnesium. Provides stable arc and low cost.

WT20 (2% Thoriated Tungsten)

Color Code: Red

Composition:

97.3% W, 1.7–2.2% ThO₂

Applications & Benefits:

Excellent arc starting and longevity. Ideal for DC welding of carbon and stainless steel.

WC20 (2% Ceriated Tungsten)

Color Code: Grey

Composition:

97.5% W, 1.8–2.2% CeO₂

Applications & Benefits:

Easy arc ignition, good for low-current TIG welding applications.

WL15 / WL20 (Lanthanated Tungsten)

Color Code: Blue / Gold

Composition:

W + 1.5–2% La₂O₃

Applications & Benefits:

Great all-purpose electrode suitable for both AC & DC currents. Long life and stability.

WZ8 (Zirconiated Tungsten)

Color Code: White

Composition:

W + 0.8% ZrO₂

Applications & Benefits:

Excellent for AC welding of aluminum with minimal contamination.

Types of Tungsten Electrodes for TIG Welding

We offer a comprehensive range of Tungsten Electrodes for TIG Welding:

WCe20

Cerium-Tungsten Electrode

Best for low-current welding, excellent arc-starting, and long service life.

WT10 / WT20 / WT30 / WT40

Thoriated Tungsten Electrodes

Ideal for high amperage DC welding.

WL10 / WL15 / WL20

Lanthanated Tungsten Electrodes

Popular choice with high current resistance and minimal burn loss.

WZr8

Zirconium-Tungsten Electrode

High corrosion resistance and superior performance in AC welding.

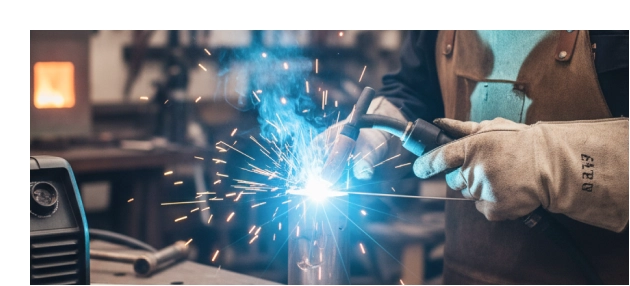

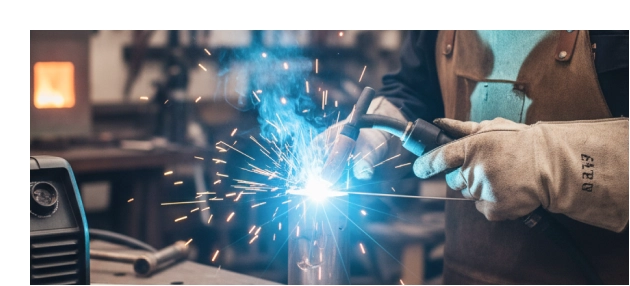

Key Features

- Superior Heat Resistance: Performs effectively at high temperatures up to 3,400°C.

- Excellent Arc Stability: Ensures clean starts, steady arcs, and smooth welds.

- Low Burn-Off Rate: Reduces electrode consumption and downtime.

- High Thermal & Electrical Conductivity: Provides better current flow for precise control.

- Contamination-Free Welds: Ideal for stainless steel, aluminum, and non-ferrous metals.

- Available in Multiple Grades: Pure (WP), Thoriated (WT20), Ceriated (WC20), Lanthanated (WL15/20), and Zirconiated (WZ8).

- Custom Lengths & Diameters: Available as rods, bars, or pre-ground electrodes.

Applications

TIG welding of stainless steel, aluminum, copper, and nickel alloys

Aerospace & automotive component fabrication

Power plants and energy sector welding

Shipbuilding and pipeline projects

Precision welding in instrumentation and electronics

Maintenance and repair of industrial equipment

Advantages

- Consistent arc ignition and re-ignition

- Reduced electrode erosion and contamination

- Longer electrode life and minimal downtime

- Cost-efficient tungsten rod price in India

- PAN India and global export availability

- Conforms to AWS A5.12 / ISO 6848 standards

Why Choose Shivshakti Metal

Leading tungsten rod manufacturer and supplier in India

Comprehensive TIG electrode range for every welding application

Competitive tungsten rod and bar prices

Export-ready with international packaging standards

Custom manufacturing available upon request

Technical assistance for product selection and compatibility

FAQs

1. What are tungsten rods used for?

Tungsten rods are primarily used as non-consumable electrodes in TIG welding, known for precision, arc stability, and durability.

2. Which tungsten electrode is best for stainless steel welding?

2% Thoriated (WT20) or 2% Lanthanated (WL20) tungsten electrodes are ideal for DC welding of stainless steel.

3. What is the difference between pure and alloyed tungsten electrodes?

Pure tungsten (WP) is used for AC welding, while alloyed electrodes (Thoriated, Ceriated, etc.) offer better performance in DC or mixed polarity welding.

4. Do you supply tungsten bars for industrial use?

Yes, we supply tungsten bars and rods in various diameters and lengths for fabrication and electrode manufacturing.

5. Do you export tungsten rods internationally?

Yes. Shivshakti Metal exports tungsten rods and TIG electrodes to global markets with full quality certification.

Request a Quote

Related Products

Tungsten Rods

High-performance non-consumable electrodes designed for TIG welding — offering superior arc stability, long life, and precision control.

Explore Tungsten Rods

Welding Torches

Durable and ergonomic torches suitable for both manual and automated welding processes, ensuring smooth current delivery and consistent weld quality.

Explore Welding Torches

Welding Nozzles

Precisely engineered nozzles that ensure accurate shielding gas flow, prevent contamination, and maintain consistent weld bead quality.

Explore Welding Nozzles

Welding Accessories

A complete range of welding machine consumables and accessories including collets, diffusers, liners, and tips designed to maximise productivity and reduce operational costs.

Explore Welding Accessories