SAW Welding Machines

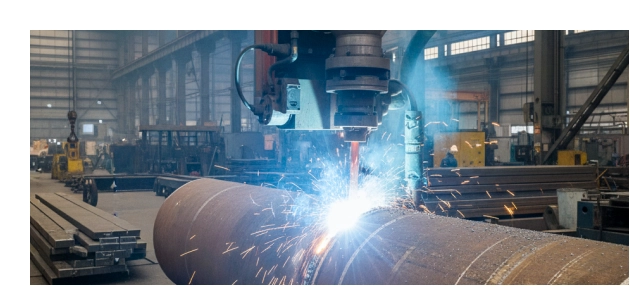

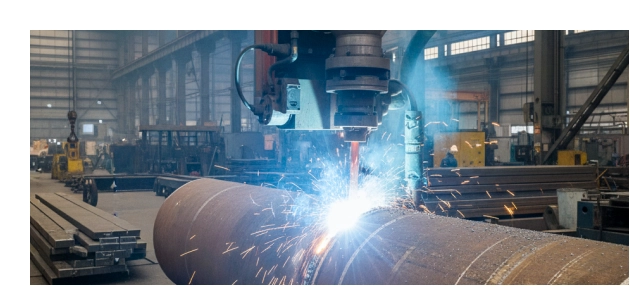

High-performance Submerged Arc Welding (SAW) Machines engineered for deep penetration, heavy-duty fabrication, and industrial reliability.

About SAW Welding Machines

At Shivshakti Metal, we are a trusted distributor of Lincoln Electric and WARPP SAW (Submerged Arc Welding) machines in India, delivering robust, high-efficiency welding solutions for shipbuilding, structural fabrication, pipelines, and heavy industry.

Submerged Arc Welding (SAW) — also known as Sub Arc Welding — is a high-productivity process where a continuously fed wire electrode operates beneath a granular flux layer, producing deep-penetration, clean welds with minimal spatter.

Our automatic and semi-automatic SAW welders are designed for demanding environments, offering:

- High deposition rates and deep penetration

- Continuous, high-strength welds

- Reduced operational costs and maintenance needs

As an authorised SAW welding machine distributor, Shivshakti Metal provides the Lincoln Electric SAW series and WARPP SAW systems, known globally for their stability, productivity, and reliability.

From heavy fabrication to offshore structures, our machines ensure consistent weld integrity and long-term performance across all applications.

Our Range of Products

Idealarc DC1000

Features:

- 500 amp output connections with excellent arc characteristics

- Single range control for easy operation

- Terminal strip and output studs for flexible connections

Input:

Output:

Output:

Input: 3-Phase, 50/60Hz

Output: CC/DC, CV/DC

Applications: Submerged Arc Welding (SAW), MIG welding, heavy fabrication

Product Inquiry

Idealarc DC1500

Features:

- Line voltage compensation ensures consistent welds

- Fan-cooled electronics prevent overheating

- Windings & rectifiers designed against moisture and corrosion

Input:

Output:

Output:

Input: 3-Phase, 50/60Hz

Output: CC/DC, CV/DC

Applications: Structural welding, shipbuilding, industrial fabrication

Product Inquiry

Flextec 650

Features:

- Streamlined operator panel reduces setup time

- Designed for long service life in high-temperature environments

- IP-23 rated for use in harsh conditions

Input:

Output:

Output:

Input: 3-Phase, 50/60Hz

Output: CC/DC, CV/DC

Applications: Oil & gas pipelines, power plants, fabrication workshops

Product Inquiry

Idealarc AC1200

Features:

- Standard Scott® connection for dual AC welding heads

- Rheostat for adjusting output during welding or idle

- Three output studs with overlapping ranges

Input:

Output:

Output:

Input: 1-Phase, 50/60Hz

Output: CC/AC, CV/AC

Applications: Heavy-duty AC welding, industrial applications, large structures

Product Inquiry

Power Wave AC/DC 1000SD

Features:

- 380–575 VAC, 50/60Hz input – connectable worldwide

- Easy parallel operation for multiple arcs

- Eliminates the imbalance common with transformer-based AC welders

Input:

Output:

Output:

Input: 3-Phase, 380–575 VAC

Output: CC/DC, CV/DC, AC/DC

Applications: Aerospace, shipbuilding, multiple-arc heavy fabrication

Product InquiryKey Features

- High Deposition Rates: Ensures faster welding for large-scale fabrication.

- Energy Efficient: Inverter-based power systems for optimal current control.

- Excellent Arc Stability: Produces smooth, uniform welds with minimal slag.

- Rugged Build Quality: Built to perform in harsh industrial environments.

- Flexible Configurations: Available in DC, AC, and AC/DC variants.

- Automation Ready: Compatible with automatic welding heads and manipulators.

- Long Service Life: Designed for low maintenance and consistent performance.

Applications

Our Submerged Arc Welding (SAW) machines are used in industries requiring strong, deep, and clean welds:

Heavy-duty industrial fabrication

Shipbuilding & offshore structures

Oil & gas pipelines

Power plants & pressure vessels

Infrastructure & steel construction

Machinery and boiler manufacturing

Advantages

Deep Weld Penetration

High Welding Speed

Minimal Spatter

Enhanced Safety

Cost Efficiency

Multi-Arc Options

Why Choose Shivshakti Metal for SAW Welding Machines?

Leading SAW Welding Machine distributor and importer in India

Wide range of automatic & manual sub arc welders

Competitive SAW welding machine prices for every industry

PAN India distribution and global export support

Technical assistance, consumables & spare parts availability

Genuine Lincoln SAW welding equipment with warranty

FAQs

1. What is SAW Welding?

SAW (Submerged Arc Welding) is an automated process where an electric arc forms between a continuously fed electrode and the workpiece under a layer of flux. It’s ideal for deep, strong welds in thick materials.

2. What is the price of SAW Welding Machines in India?

The SAW welding machine price varies by model, output capacity, and automation level. Contact Shivshakti Metal for the most competitive pricing in India.

3. What are the advantages of SAW welding over other methods?

4. Do you supply automatic SAW welding machines?

Yes. We manufacture and supply automatic Sub Arc Welders for high-volume, continuous welding applications.

5. Are your SAW welders export-ready?

Absolutely. Shivshakti Metal exports SAW welding machines worldwide, ensuring reliable packaging, service, and global support.

Request a Quote

Related Products

TIG Welding Machines

Our TIG welders deliver precise, high-quality welds with excellent finish, making them the choice for industries requiring accuracy and control.

Applications: Aerospace, automotive, stainless steel fabrication, and precision welding.

Explore TIG Welders

MIG Welding Machine

Our MIG welding machines deliver clean, strong welds with minimal spatter. Ideal for thin materials and production environments, they are known as one of the best welding machines for ease of use.

Applications: Automotive workshops, sheet metal fabrication, repair and maintenance.

Explore MIG Welders

SMAW Welding Machines

Stick welding machines (SMAW) are versatile and economical, capable of welding different metals and thicknesses even in outdoor conditions.

Applications: Construction, maintenance, field welding, and heavy fabrication.

Explore Stick Welders (SMAW)

SAW Welding Machines

Our SAW welders are engineered for deep weld penetration and heavy-duty applications. They are highly efficient for continuous, long welds with superior strength.

Applications: Shipbuilding, pipelines, pressure vessels, and structural steel fabrication.

Explore SAW Welders

Laser Welding Machines

Our Laser Welding Machines offer unmatched precision, speed, and strength—ideal for modern manufacturing that demands flawless joints and minimal heat distortion.

Applications: Electronics, medical devices, automotive, jewelry, and precision engineering.

Explore Laser Welding

Plasma Machines

Our plasma machines provide powerful, smooth, and efficient metal cutting for industrial and on-site applications. Backed by Lincoln Electric and Wrapp technology, these systems ensure precision, durability, and consistent performance across all materials.

Applications: Fabrication, Automotive, Construction, Manufacturing, and Prototyping

Explore Plasma Machine