Flux Cored Wire Manufacturer & Supplier in India

Top Manufacturer and Exporter of Flux Cored Welding Wires for Stainless Steel and Carbon Steel in India

About Flux Cored Wire

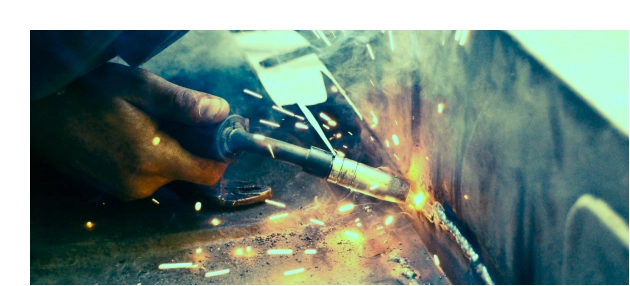

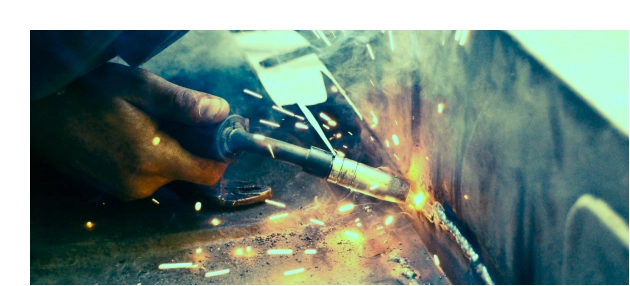

At Shivshakti Metal, we are a trusted flux cored wire manufacturer in India, delivering premium quality cored wires for MIG and TIG welding. Our products are engineered for high efficiency, consistent arc stability, and smooth weld finishes. Whether you’re welding stainless steel or medium-carbon steel, our solutions ensure excellent performance for critical applications.

We supply flux cored welding wires across multiple grades, tailored for industries such as shipbuilding, structural fabrication, pressure vessels, and more. As one of the top flux cored wire suppliers, we also offer competitive flux cored wire prices with no compromise on quality.

Grade Specifications

E308LT1-1 Flux Cored Wire

Composition (%): C: 0.032, Mn: 1.2, Si: 0.8, Cr: 19.5, Ni: 10, P: 0.015

Applications:

Suitable for welding 301, 302, 304, 304L, 308, and 308L stainless steel. Ideal for out-of-position welding.

E316LT1-1 Flux Cored Wire

Composition (%): C: 0.038, Mn: 1.3, Si: 0.9, Cr: 18.5, Ni: 12.3, Mo: 2.5, P: 0.015

Applications:

Best for welding 316 and 316L stainless steel.

E309LT1-1 Flux Cored Wire

Composition (%): C: 0.032, Mn: 1.2, Si: 0.5, Cr: 22.25, Ni: 12.25

Applications:

Used for welding type 309 in cast or wrought form, also ideal for joining type 304 to mild steel.

E347T1-1 Flux Cored Wire

Composition (%): C: 0.032, Mn: 1.2, Si: 0.9, Cr: 19.6, Ni: 9.6, P: 0.018

Applications:

For welding 347, 304, 304L, and 321 stainless steels, especially for service temperatures below 600°F.

E309LMoT1-1 Flux Cored Wire

Composition (%): C: 0.032, Mn: 1.2, Si: 0.8, Cr: 23.15, Ni: 14.15, Mo: 2.45, P: 0.014

Applications:

Designed for all-position welding of stainless steel to mild or carbon steel.

E2209T1-1 Flux Cored Wire

Composition (%): C: 0.03, Mn: 0.95, Si: 0.8, Cr: 22.5, Ni: 9.0, Mo: 3.0

Applications:

Used in welding duplex stainless steels for high strength and corrosion resistance.

Key Features

- Smooth arc stability and spatter control

- Excellent weld bead appearance

- Ideal for out-of-position welding

- Low fume generation

- High deposition rate

Applications

Pressure vessels & boilers

Offshore & marine structures

Pipelines & oil rigs

Automotive frames

Structural steel fabrication

Industries We Serve

Petrochemical

Shipbuilding

Power Generation

Construction

Railways and Infrastructure

Why Choose Fusion WireTM ️for Flux Cored Wire?

As a leading flux-cored wire manufacturer and supplier in India, we offer:

Certified manufacturing under stringent quality controls

Custom sizes and packaging as per client needs

Reliable delivery across India and abroad

Competitive flux cored wire price without compromising quality

We also supply flux core aluminum welding rods, supporting industries that demand high-strength, corrosion-resistant solutions.

FAQs

1. What is flux-cored wire used for?

Flux-cored wires are used in MIG and TIG welding to provide high deposition rates and better penetration, especially for out-of-position and thick-section welds.

2. Do you supply flux-core aluminium welding rods?

Yes, we supply flux-core aluminium welding rods as per application needs.

3. Can I get custom sizing or packaging?

Absolutely! We provide custom lengths and spool packaging based on your welding requirements.

Request a Quote

Related Products

TIG Welding Wire

Designed for high-precision welding of stainless steel and alloy metals.

View Details

MIG Welding Wire

Ensures high productivity with smooth feedability for fabrication industries.

View Details

SAW Welding Wire

Ideal for heavy-duty applications like pipelines, shipbuilding & structures.

View Details

Flux Cored Welding Wire

Ensures deep penetration and high-strength welding for heavy-duty applications.

View Details