MIG Welding Wire Manufacturer

Range of high-quality MIG welding wires designed for durability, precision, and cost-effective performance.

About MIG Wire

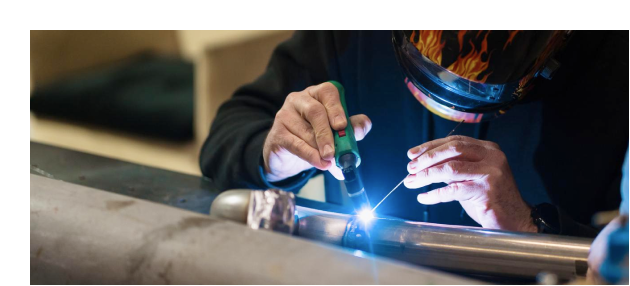

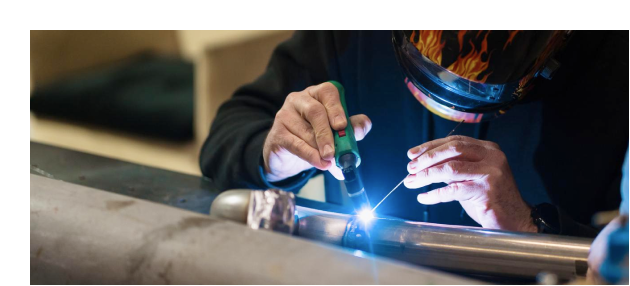

MIG Wire, also known as Metal Inert Gas welding wire, is a consumable electrode used in the MIG welding process. Continuously fed through a welding gun, the wire melts to create strong, clean weld joints while being protected by shielding gases like CO₂, Argon, or mixed compositions.

At Shivshakti Metal, we are a trusted MIG wire manufacturer in India, offering superior quality welding wires at competitive prices. With our advanced manufacturing facility in Ahmedabad, Gujarat, we supply to industries across India and export worldwide. Our focus on performance, consistency, and cost-efficiency makes us one of the top MIG wire suppliers in the market.

Whether you need wires for manual fabrication, automated welding lines, or specialized applications, we deliver the best MIG welding wire solutions tailored to your needs.

Grade Specifications

Shivshakti Metal provides a complete range of MIG welding wire grades for diverse industrial applications.

ER308 / ER308H MIG Welding Wire

Material : 18% Cr – 8% Ni

Form: MIG Wire (Spools / Coils)

Mechanical Properties:

Tensile Strength – 570 N/mm² (83 ksi)

Elongation – 41%

Applications:

For welding stainless steels such as 301, 302, 304, 304H, 305, 308 & 308H.

ER308L MIG Welding Wire

Material : Low carbon 18% Cr – 8% Ni

Sizes Available: 0.8, 1.0, 1.2, 1.6 mm (custom sizes available)

Mechanical Properties:

Tensile Strength – 570 N/mm² (83 ksi)

Elongation – 41%

Applications:

For welding low carbon stainless steels with improved corrosion resistance.

ER308LSi MIG Welding Wire

Material: Matches AISI 301, 302, 304, 304L, 305, 308, 308L & 347

Properties: High silicon content for smooth bead appearance

Used to weld base metals of similar composition in stainless fabrication.

ER309L MIG Welding Wire

Material: 22% Cr – 12% Ni

Sizes Available: 0.8, 1.0, 1.2, 1.6 mm

Mechanical Properties:

Tensile Strength – 570 N/mm² (83 ksi)

Elongation – 40%

Applications:

For welding stainless steels and dissimilar steels (stainless to mild steel).

ER309LSi MIG Welding Wire

Material: High silicon, 23.50% Cr – 12.95% Ni

Properties: Improves bead appearance & weldability

Applications: Welding of dissimilar materials and stainless overlays.

ER309LMo MIG Welding Wire

Material: 24.10% Cr – 12.9% Ni – 2.4% Mo

Properties: Joining stainless steels, heat-resistant chromium steels, and overlay cladding requiring Mo for corrosion resistance.

ER310 MIG Welding Wire

Material: 26.50% Cr – 21.08% Ni

Mechanical Properties:

Yield Strength – 420 N/mm²

Tensile Strength – 580 N/mm²

Elongation – 37%

Applications:

For welding type AISI 310 stainless steel and high-temperature alloys.

ER316L MIG Welding Wire

Material: 18% Cr – 12% Ni – 2.5% Mo

Sizes Available: 0.8, 1.0, 1.2, 1.6 mm

Mechanical Properties:

Tensile Strength – 550 N/mm² (80 ksi)

Elongation – 41%

Applications:

For low-carbon molybdenum stainless steels with excellent corrosion resistance (marine & chemical industries).

ER316LSi MIG Welding Wire

Material: 18% Cr – 12.6% Ni – 2.5% Mo, high Si

Applications:

Provides better bead appearance & weldability in stainless steels.

ER317 / ER317L MIG Welding Wire

Material : 19% Cr – 13.5% Ni – 3.5% Mo

Mechanical Properties:

Yield Strength – 410 N/mm²

Tensile Strength – 570 N/mm²

Elongation: 39%

Applications:

For stainless steels with higher molybdenum content; excellent resistance to pitting and crevice corrosion.

ER318 MIG Welding Wire

Material : Equivalent to 316Ti base metal

Applications:

For welding Grade 316Ti stainless steels.

ER320 MIG Welding Wire

Material: 19.7% Cr – 33.5% Ni + Mo, Cb, Ta, Cu

Mechanical Properties:

Yield Strength – 460 N/mm²

Tensile Strength – 610 N/mm²

Elongation: 41%

Applications:

Welding high-alloy stainless steels with excellent corrosion resistance.

ER347 / ER347L MIG Welding Wire

Material : 20.22% Cr – 9.87% Ni, Nb stabilized

Mechanical Properties:

Yield Strength – 450 N/mm²

Tensile Strength – 616 N/mm²

Elongation – 39%

Applications:

For welding stabilized stainless steels such as 321 and 347; prevents intergranular corrosion.

ER410 MIG Welding Wire

Material : 12.93% Cr – 0.42% Mo

Mechanical Properties:

Tensile Strength – 530 N/mm²

Elongation – 35%

Applications:

Welding martensitic stainless steels (403, 410, 416) and overlays on carbon steels.

ER410NiMo MIG Welding Wire

Material : 12.15% Cr – 4.12% Ni – 0.62% Mo

Mechanical Properties:

Yield Strength – 850 N/mm²

Tensile Strength – 950 N/mm²

Elongation – 17%

Applications:

Welding cast & wrought steels of similar composition, with high strength and wear resistance.

ER383 MIG Welding Wire

Material : 29.2% Cr – 36.4% Ni with Mo & Nb

Mechanical Properties:

Yield Strength – 350 N/mm²

Tensile Strength – 550 N/mm²

Elongation – 30%

Applications:

For alloys like 825, 28, and 20; excellent resistance to aggressive chemical environments.

ER385 MIG Welding Wire

Material : 20.2% Cr – 25.6% Ni – 4.52% Mo – 1.5% Cu

Mechanical Properties:

Yield Strength – 410 N/mm²

Tensile Strength – 610 N/mm²

Elongation – 35%

Applications:

For fabrications handling sulfuric acid and chloride-containing environments (chemical plants, refineries).

ER312 MIG Welding Wire

Material : 29.85% Cr – 9.05% Ni

Mechanical Properties:

Yield: 620 N/mm²

Tensile: 770 N/mm²

Elongation: 27%

Applications:

Welding dissimilar steels, high-strength, and high-yield steels.

ERNi-1 MIG Welding Wire

Material Composition: Nickel (Ni) ~96%, Titanium (Ti) ~3%, Low Carbon

Form: MIG Wire (Spools / Coils)

Mechanical Properties:

Tensile Strength: ~480–550 N/mm²

Elongation: ~35–40%

Applications:

Nickel-to-nickel joints, Corrosion repair, Heat exchangers and desalination systems

ERNiCr-3 MIG Welding Wire

Material Composition: Nickel (Ni) ~65%, Chromium (Cr) 20–23%, Molybdenum (Mo), Titanium (Ti)

Form: MIG Wire (Spools / Coils)

Mechanical Properties:

Tensile Strength: ~550–620 N/mm²

Stable mechanical properties at high temperatures

Applications:

Welding stainless steel to nickel alloy, Power generation and gas turbine components

ERNiCrMo-3 MIG Welding Wire

Material Composition: Nickel (Ni) ~58%, Chromium (Cr) ~22%, Molybdenum (Mo) ~9%, Niobium (Nb)

Form: MIG Wire (Spools / Coils)

Mechanical Properties:

Tensile Strength: ~760–830 N/mm²

High yield strength with excellent ductility

Applications:

Fabrication of corrosion-resistant components, Offshore, marine, and seawater-exposed structures

ERNiCrMo-4 MIG Welding Wire

Material Composition: Nickel (Ni) ~57%, Chromium (Cr) ~16%, Molybdenum (Mo) ~16%, Iron (Fe), Tungsten (W)

Form: MIG Wire (Spools / Coils)

Mechanical Properties:

Tensile Strength: ~760–800 N/mm²

High strength with excellent ductility under corrosive conditions

Applications:

Fabrication of corrosion-resistant equipment

Chemical and petrochemical plant

ERNiCrMo-13 MIG Welding Wire

Material Composition: Nickel (Ni) ~57%, Chromium (Cr) ~20–22%, Molybdenum (Mo) ~16%, Tungsten (W)

Form: MIG Wire (Spools / Coils)

Mechanical Properties:

Tensile Strength: ~760–800 N/mm²

High strength with excellent ductility in corrosive environments

Applications:

Fabrication of corrosion-resistant equipment

ERNiFeCr-1 MIG Welding Wire

Material Composition: Nickel (Ni) ~52%, Chromium (Cr) ~19%, Iron (Fe), Niobium (Nb), Molybdenum (Mo)

Form: MIG Wire (Spools / Coils)

Mechanical Properties:

Tensile Strength: ~760–880 N/mm²

Maintains strength at high temperatures

Applications:

Automated welding of nickel alloy components

ERNiFeCr-2 MIG Welding Wire

Material Composition: Nickel (Ni) ~52%, Chromium (Cr) ~19%, Iron (Fe), Niobium (Nb), Molybdenum (Mo)

Form: MIG Wire (Spools / Coils)

Mechanical Properties:

Tensile Strength: ~760–880 N/mm²

Good toughness under high pressure conditions

Applications:

Automated welding of pressure-bearing components

ERNiCu-7 MIG Welding Wire

Material Composition: Nickel (Ni) ~65%, Copper (Cu) ~30%, Iron (Fe)

Form: MIG Wire (Spools / Coils)

Mechanical Properties:

Tensile Strength: ~480–550 N/mm²

Stable arc with good weld bead appearance

Applications:

Fabrication of marine components

Key Features

- Superior Feedability – Smooth wire feeding even at high welding speeds.

- Low Spatter, Clean Welds – Reduced rework and improved productivity.

- Excellent Arc Stability – Consistent penetration and strong weld joints.

- Wide Material Compatibility – Works with stainless steel, mild steel, alloy steels, and special grades.

- Corrosion-Resistant Packaging – Ensures long shelf life and performance during storage.

- Gas Compatibility – Performs excellently with CO₂, Argon, and Argon-CO₂ mixtures.

Applications

Our MIG wires are widely used in:

Automotive & transport (frames, exhausts, body panels)

Fabrication shops (railings, gates, furniture)

Construction (beams, structures, bridges)

Shipbuilding & offshore engineering

Oil, gas & pipeline welding

Agricultural equipment manufacturing

Industries We Serve

Automotive & Aerospace Industries

Oil & Gas

Heavy Engineering & Fabrication

Power & Energy

Shipbuilding & Marine

Steel & Metal Industries

Why Choose Fusion WireTM for MIG Wires?

One of the top MIG wire manufacturers in India

Competitive MIG wire price with quality assurance

Advanced production technology ensures precision

PAN India presence + strong export supply

Customised MIG wire types available for special industrial needs

FAQs

1. What is MIG Wire?

MIG Wire, also called Metal Inert Gas welding wire, is a consumable electrode used in MIG welding. It is continuously fed through a welding gun, melts to create strong joints, and is protected by shielding gases like Argon, CO₂, or a mixture.

2. What are the types of MIG Welding Wire?

Common MIG wire types include:

- ER70S-6 (Carbon Steel MIG Wire): For mild & low alloy steels.

- ER308 / ER308L (Stainless MIG Wire): For stainless steel grades 301, 302, 304, 308.

- ER309 / ER309L (Dissimilar Steel Wire): For joining stainless steel to carbon steel.

- ER316L (Stainless with Molybdenum): For corrosion-resistant stainless applications. Each type is selected based on the base material and application.

3. What is the price of MIG Welding Wire in India?

The MIG wire price in India varies depending on grade, diameter, packaging, and quantity. Shivshakti Metal offers competitive prices while ensuring premium quality. For bulk orders or specific grades, contact us for a customized quote.

4. Who are the leading MIG Wire manufacturers and suppliers in India?

Shivshakti Metal is among the top MIG wire manufacturers in India, supplying across Ahmedabad, Gujarat, and pan-India, with exports worldwide. Our MIG wires are trusted by industries for consistent performance and long-term value.

5. What industries use MIG Welding Wire?

MIG welding wires are widely used in:

- Automotive & aerospace

- Oil & gas pipeline welding

- Construction & infrastructure

- Shipbuilding & marine

- General fabrication & engineering

6. How to choose the best MIG Welding Wire?

Choosing the best MIG wire depends on:

- The base material (mild steel, stainless steel, alloys)

- Shielding gas available (CO₂, Argon, or mixed gases)

- Application (fabrication, pipelines, shipbuilding, etc.)

- Required strength & corrosion resistance

Our technical team helps clients select the right MIG wire for maximum productivity.

7. Do you supply MIG wire outside India?

Yes, Shivshakti Metal is a global MIG welding wire exporter. We supply to various countries with safe packaging, timely delivery, and bulk order support.

Request a Quote

Related Products

TIG Welding Wire

Designed for high-precision welding of stainless steel and alloy metals.

View Details

MIG Welding Wire

Ensures high productivity with smooth feedability for fabrication industries.

View Details

SAW Welding Wire

Ideal for heavy-duty applications like pipelines, shipbuilding & structures.

View Details

Flux Cored Welding Wire

Ensures deep penetration and high-strength welding for heavy-duty applications.

View DetailsStill unsure about the MIG Welding Wire for your application?

Ahmedabad | PAN India Delivery